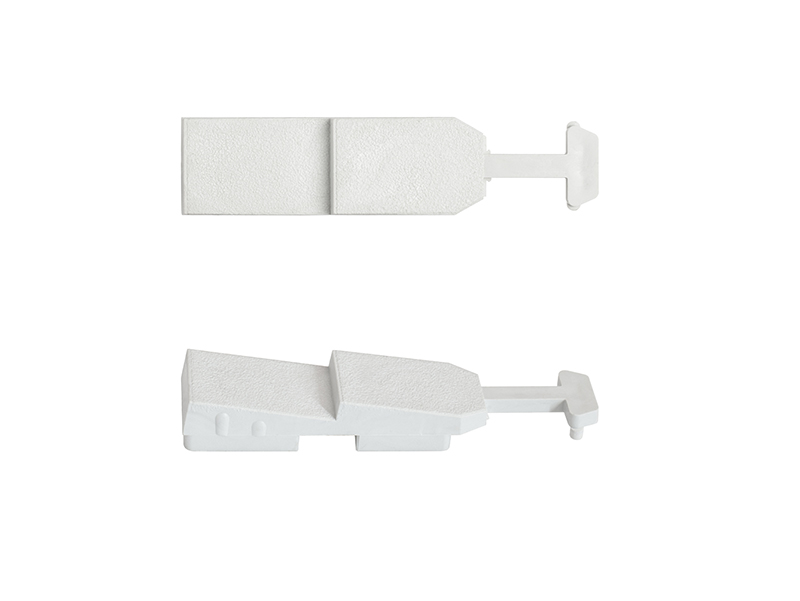

Manufacture and sale of door welding corners designed for plastic entrance doors in order to improve the torsional rigidity of the sash. The products are made exclusively from recycled PVC window profiles without any additional additives and thus guarantee smooth weldability and maximum weld strength. The welding corners are applied to the reinforcement by means of a tearing (fixing) lever - it is therefore a tearing model of the welding corner.

Our products are suitable for plastic door profile systems VEKA, PROFINE, TROCAL, KOMMERLING, KBE, REHAU, SCHUCO, ALUPLAST, INOUTIC, DECEUNICK and SALAMANDER.

The production of these products is ensured by plastic injection on modern ARBURG machines with pre-drying of the input material and nitrided injection chamber and screws, robotic automation of FANUC handling of injected parts and a folding machine for assembling products into a folded state. Production capacity is 50,000 - 100,000 pcs / month. The quality of the injection molds is maintained in our own tool shop with ultrasonic cleaning baths.